Morton Machinery Company, a leading high-technology based knitting machine design, manufacture, and service provider, has announced the launch of their latest knitting machine conversion kit. This innovative solution is set to revolutionize the garment and textile industries, providing a cost-effective and efficient way to upgrade existing knitting machines and improve productivity.

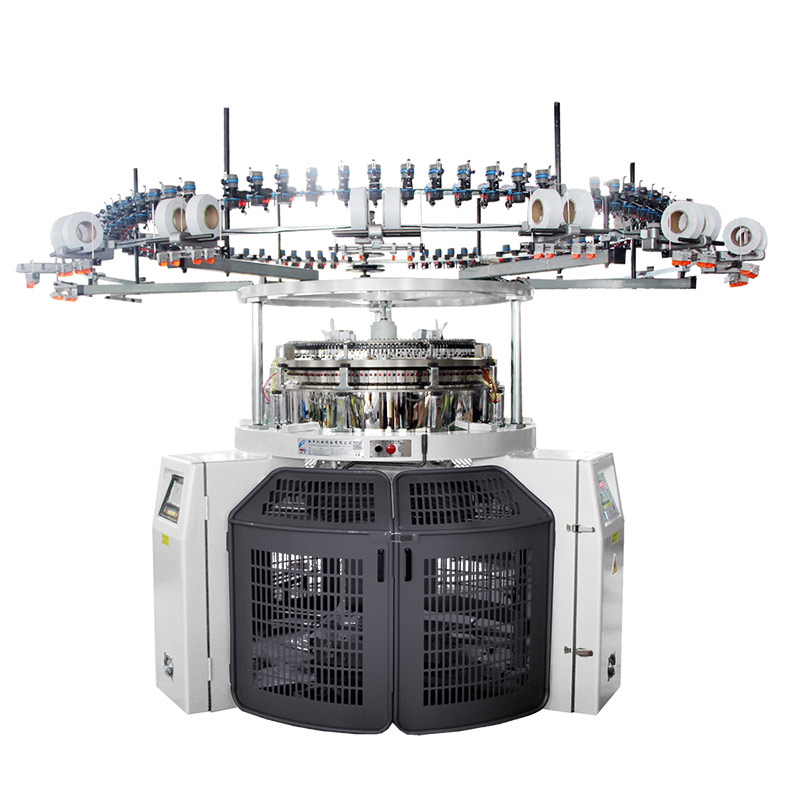

The knitting machine conversion kit is designed to be compatible with a wide range of knitting machines, including Single Jersey Machine, Fleece Machine, Jacquard Machine, Rib Machine, Open Width Machine, and other related products. This versatility means that textile manufacturers can easily retrofit their existing equipment with the latest technology, avoiding the need for expensive and time-consuming replacements.

The conversion kit offers a range of benefits, including improved efficiency, reduced downtime, and increased production capacity. By incorporating state-of-the-art technology, Morton Machinery Company aims to enable their customers to remain competitive in the rapidly evolving textile industry.

"We are excited to introduce our knitting machine conversion kit to the market," said a spokesperson for Morton Machinery Company. "With this innovative solution, we are empowering textile manufacturers to modernize their equipment and achieve higher levels of productivity without having to invest in completely new machinery. This represents a significant cost saving and ensures that our customers can stay ahead in a highly competitive industry."

In addition to enhancing productivity, the knitting machine conversion kit also offers improved precision and quality control. This is achieved through the integration of advanced sensors and monitoring systems, which enable operators to closely monitor the knitting process and identify any potential issues before they affect the final product. This level of control and oversight is essential for maintaining high standards of quality in an industry where even minor defects can have significant repercussions.

Furthermore, the conversion kit is designed with sustainability in mind, incorporating energy-efficient components and processes that contribute to a reduced environmental impact. By optimizing the use of resources and minimizing waste, Morton Machinery Company is helping textile manufacturers to operate in a more environmentally responsible manner, meeting the growing demand for sustainable production practices.

The release of the knitting machine conversion kit reaffirms Morton Machinery Company's commitment to leveraging cutting-edge technology to drive progress in the textile industry. With a track record of innovation and a dedication to meeting the evolving needs of their customers, Morton Machinery Company has established a reputation as a leading provider of solutions for the garment and textile industries.

As the textile industry continues to undergo rapid transformation, the introduction of the knitting machine conversion kit represents a significant milestone in the quest for greater efficiency, sustainability, and competitiveness. By offering a cost-effective way for manufacturers to modernize their equipment and optimize their operations, Morton Machinery Company is poised to play a key role in shaping the future of textile production.

As interest in the knitting machine conversion kit grows, Morton Machinery Company is confident that their innovative solution will be embraced by textile manufacturers seeking to stay ahead in a dynamic and demanding market. With its combination of advanced technology, cost savings, and environmental benefits, the knitting machine conversion kit has the potential to redefine the way that textiles are produced and pave the way for a more efficient and sustainable industry.